Hands on 3D printing classes to be offered in fall 2015

May 20, 2015

You might have heard about the world’s first 3D-printed gun, NASA’s 3D printer on the International Space Station, or even printed chocolate and wonder how 3D printing really works.

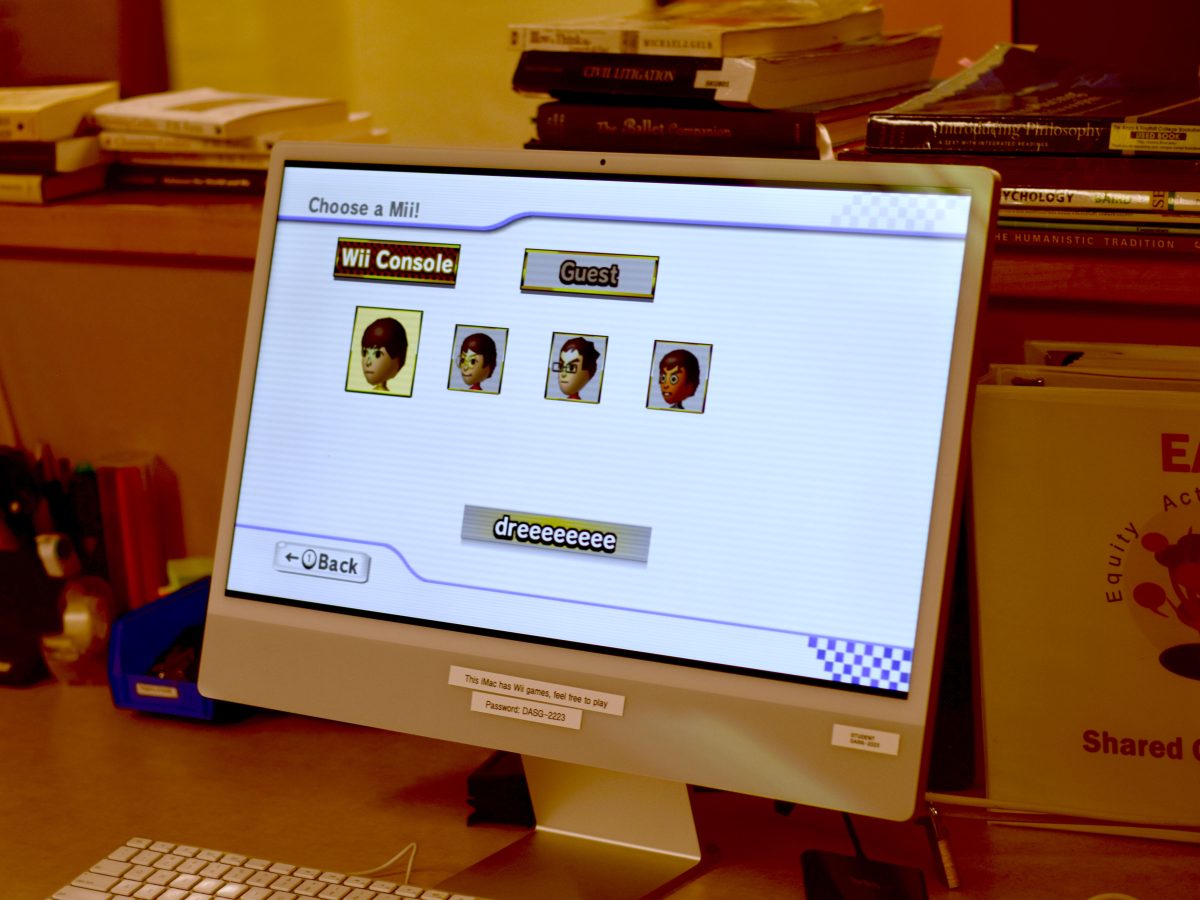

You can even find a $50,000 low end industrial printer in action at the Computer Aided Design and Manufacturing Department.

Students will have the opportunity to take a hands-on, real world application 3D printing class beginning fall of 2015 said Max Gilleland, the CAD department’s computer lab instructor.

The class will focus on learning to use CAD software and students will have the opportunity to print small objects.

The department will also be receiving another printer in the fall of 2015.

There will be a 3D printing demonstration from Stratasys engineers and a speaker about reverse engineering on June 25 in the CAD lab. The event will be limited to 75 attendees, so make sure to reserve a space if you’re interested at the CAD lab located in E35.

3D printing is used to make prototype-like objects and functional parts like prosthetics, casts, car parts, and even food.

The process of 3D printing an object begins with the design. A computer aided design software is an automated drafting process used to make models. After creating a 3D model or using a model from the Internet, the software creates instructions for the printer and makes the data substantial one layer at a time.

The printer, a FORTUS 250MC manufactured by Stratasys, heats up two metal heads to 150 degrees and melts two spools of plastic wire like a pair of fancy hot glue guns. The spools of wire can contain different types of materials like metal, rubber or even sugar.

The process takes patience and time. A small object could take four to five hours to print one layer at a time, and some larger items can take a week.

The CAD lab also has an EScan 3D scanner, used to create a point cloud; a model made by taking many scans of an object then putting it together to make a 3D figure.

The scanner can be used to reconstruct objects with missing pieces, like ancient artifacts. A cracked dinosaur skull can be scanned and the point cloud would provide the accurate dimensions for the missing piece, which can then be printed using a 3D printer, a process known as reverse engineering.